Doors and Window Aluminum Materials Are Not Dyed, and the Main Points of Customization of Color and Framework-WJW Aluminum Supplier Aluminum

Author: WJW Aluminum Window Manufacturers

When the industrial aluminum profile is produced, what should I do when it encounters aluminum -type materials to be dyed.

1. Insufficient anode oxide film is insufficient. The solution is to check whether the anode oxidation process is standard, see whether the temperature, voltage, and conductivity are firm. The membrane thickness is up to standard.

2. The pH value of the dyeing solution is too high. At this time, the pH value can be adjusted to the standard value with methamphetamine. After the surface of the aluminum manufacturer is oxidized, the appearance is very beautiful and resistant to dirt. When producing doors and windows, aluminum materials are used to use different specifications of profiles according to different load -bearing loads, and use of supporting aluminum profile accessories. It does not need to be welded. It is more environmentally friendly. It is also easy to carry, lightweight and easy to carry.

3. After oxidation, the workpiece is placed in the sink for too long and promotes timely dyeing. If this is generated, the workpiece can be placed in an anode oxidation tank or in the nitric acid and the heel tank is appropriately activated before dyeing. good.

4, the selection of inappropriate dyes, the suitable dye is required. The aluminum row is mainly used in the refrigeration system of 10 C to -45 C in cold storage. It is the ideal evaporator of all kinds of doors and windows, aluminum materials, and refrigerators.

5. The dyes have been decomposed or mildew, and dyes need to be replaced at this time.

6. The oxidation temperature is too low, which leads to dense skin film. The widely used non -ferrous metal structure materials in the aluminum alloy manufacturer industry are used in aviation, aerospace, automobiles, machinery manufacturing, ships and chemical industries. temperature.

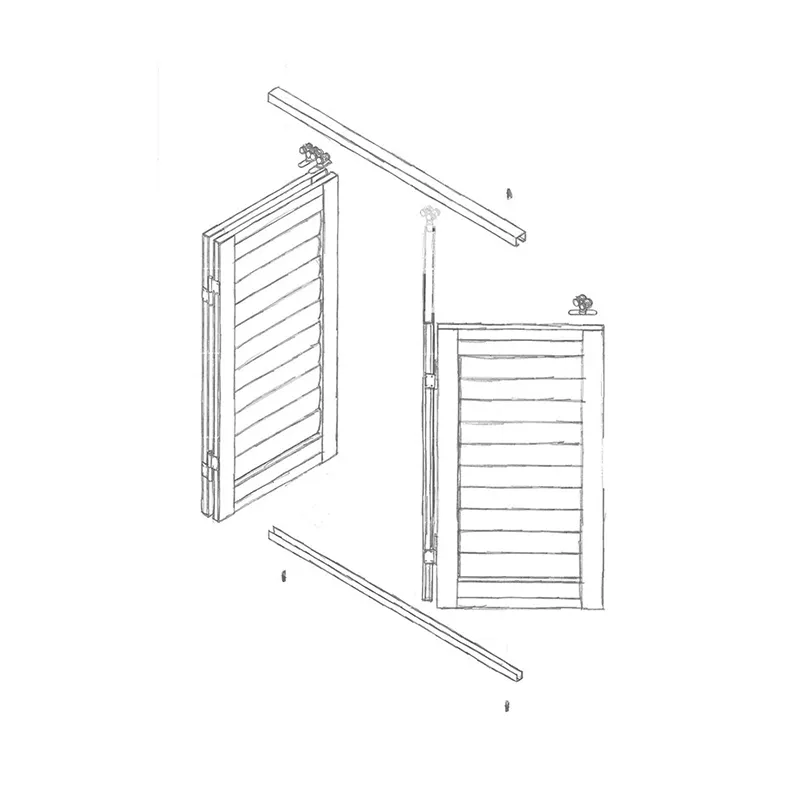

The aluminum profile framework refers to a rack that is assembled with doors and windows and windows and traveling parts or accessories. In terms of details, can we understand the attitude and strength of aluminum profile manufacturers?

First of all, the quality of the frame first depends on whether the surface of the profile is smooth, whether there are scratches and whether there are clean places.

Then observe whether there is a gap between the aluminum profile and the attachment link, or to talk about the size of the gap, whether the sealing parts are swollen, and whether the feet are firmly installed.

Then check whether the interface between the configuration file and the configuration file is neat.

After comparison, we need to check whether the machining holes and diameter of the aluminum frame are suitable and accurate. The doors and windows are aluminum.