What Problems Should Industrial Aluminum Be Paid Attention to When Spraying Technology? -WJW Aluminum Supplier Aluminum

Author: WJW Aluminum Window Manufacturers

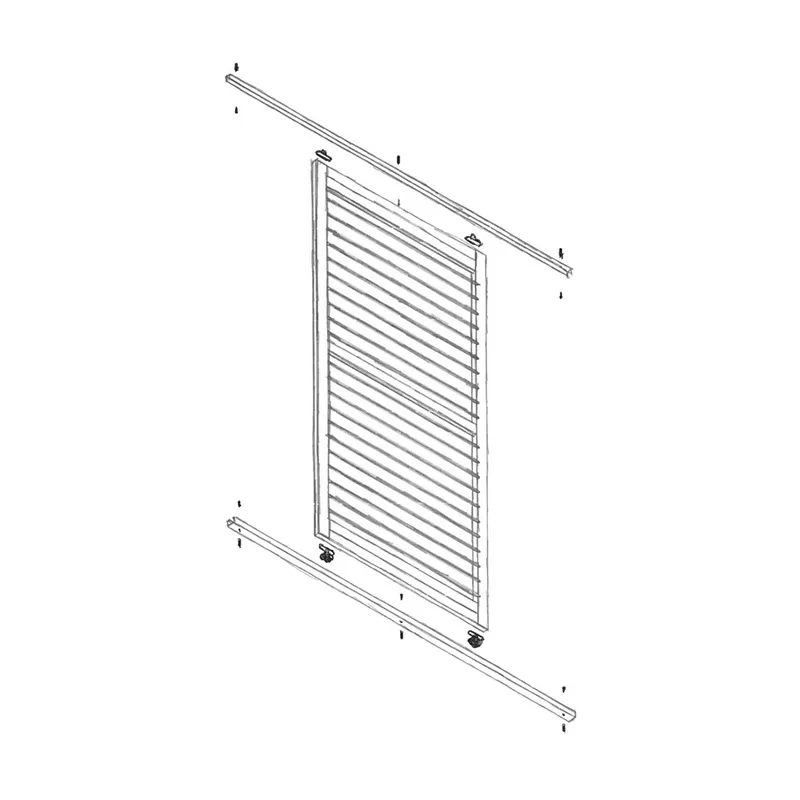

1. Selection of fixture manufacturing and feeding methods. Industrial aluminum materials are divided according to the application field. Industrial aluminum materials refer to all aluminum profiles outside the building doors and windows, curtain walls, indoor and outdoor decorations and building structures. The hot -melt squeeze of industrial aluminum materials can obtain aluminum materials with different section shapes, but the amount of alloy adds different proportion, and the mechanical properties and application areas of industrial aluminum profiles are also different. The fixtures installed at both ends should ensure that they can withstand the pressure of proportional parts; the fixtures used in the lower parts should minimize the contact point of the fixture and the nominal surface of the profile during the manufacturing and use process. The suspension position in the profile suspension of the gear shall also abide by the corresponding guidance. For some deeper profiles, the amount of powder is increased, and the distance between the spraying claw and the profile is practical and feasible. The nominal products of large or complex structures should be prohibited from the lower position, and the decorative surface and non -decorative surface of the profile should also be distinguished.

For some special profiles, the position of the fixture is adjusted in time so that the profile adheres to a certain inclined corner on the location of the pendant to strengthen the stability in the operation process, and it is easy to powder adsorption. Industrial aluminum is divided by the field of application. Industrial aluminum profile refers to all aluminum profiles outside the building doors and windows, curtain walls, indoor and outdoor decoration and building structure. In addition, for some heavier profiles to use the position next to the fixture, there should be a certain degree of arc at the elbow. The arc of the fixture can ensure that the material is in the vertical position to ensure the smooth production process. In addition, with the increase of the number of reincarnations of the suspension, the coating film will accumulate more and more. The coating itself is not conductive, which will affect the conductivity of the conductive beam and pendant, and then affect the uniform dispersing of the powder in the name of the profile.

2. The pre -processing process is simpler than the separate pre -oxidation pre -treatment sequence. The important thing is to skimmed and chromium. The consumption of raw materials is low. The daily maintenance work is absolutely easy. In order to improve the efficiency of production and reduce the energy consumption of drying process, the previous processing process uses large racks to install as much as possible. After the drying process is over, when there is still water residue, in order to avoid deformation when the nominal membrane is damaged and the temperature is too high, the profile should not be baked in the furnace. Some soft profiles should be placed more horizontally next to the profile to place the groove as much as possible, which is conducive to the evaporation of water. In addition, the profile must adhere to the appropriate tilt corner during the ticking process, but it is easy to cause local materials to slide. Therefore, it should be tied at a stainless steel wire mesh at one end of the rack to prevent it.

3. Pay attention to the spray room. You can try how many times you can spray before the formal spray. At this time, you can see the powder size and uniform powder dispersing at both ends of the spray chamber. At this time, the powder runs in the straight line within 10cm at the intervals. The outside area exists in the situation of the atomized powder. Powder that adsorbs the name of the profile is really this atomized powder. The powder of consequences is the standard for the interval between the holding claws and the profile.