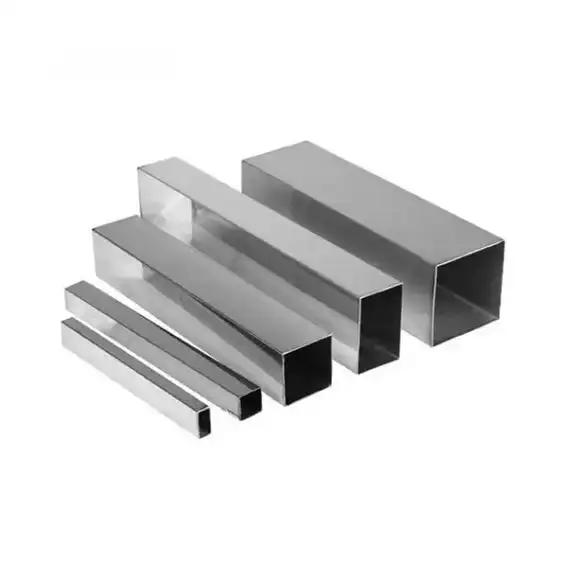

Aluminium Tube & Square

Aluminium tubes, celebrated for their lightweight nature and exceptional strength, stand as a pinnacle of versatility in diverse industries. Renowned for corrosion resistance, they find automotive, and architectural sectors, seamlessly integrating into structural frameworks and fluid transport systems. Aluminium tubes redefine efficiency and reliability, emerging as an indispensable component across varied industrial landscapes.

Our advantage

Machinability:

Aluminum is easily machinable, allowing for precision cutting, drilling, and shaping to meet specific design requirements.

Versatility in Surface Finishing:

Aluminum tubes support various surface finishes, including anodizing, powder coating, and polishing, offering aesthetic flexibility and corrosion protection.

Recyclability:

Aluminum is highly recyclable, contributing to sustainability and environmental consciousness in material choices.

Non-Magnetic:

Being non-magnetic, aluminum tubes are suitable for applications where magnetic interference is a concern.

Ease of Assembly:

Aluminum tubes are conducive to welding, brazing, and adhesive bonding, facilitating easy assembly in diverse manufacturing processes.

Resistance to UV Rays:

Resistant to UV rays, aluminum tubes maintain their appearance and structural integrity in outdoor applications.

Anodization Compatibility:

Aluminum tubes can undergo anodization, enhancing their corrosion resistance and providing a decorative finish.

Seamless Extrusion:

The extrusion process allows for the creation of seamless aluminum tubes, reducing the risk of structural weaknesses.

Key attributes

| Warranty | NONE |

| After-sale Service | Online technical support |

| Project Solution Capability | graphic design, 3D model design |

| Application |

Construction, Automotive Industry, Electrical Conduits, Sporting Goods |

| Design | StyleModern |

Other attributes

| Place of Origin | Guangdong, China |

| Brand Name | WJW |

| Position |

Structural Support, Fluid Transport, Automotive Components, Marine Applications, Architectural Design |

| Surface finish | Paint coating |

| Trade Term | EXW FOB CIF |

| Payment terms | 30%-50% deposit |

| Delivery time | 15-20days |

| Feature | Design and customize |

| Size | Free design accpeted |

Packaging and delivery

| Packaging Details | Glass, aluminum, wood, accessories |

| Port | Guangzhou or Foshan |

Lead time

| Quantity (meters) | 1-100 | >100 |

| Lead time (days) | 20 | To be negotiated |

High quality raw materials, strong compression resistance and long service life

Quality assurance, source factory, manufacturer direct supply, price advantage, short production cycle

High precision and high quality assurance Thicken and reinforce, strictly control the production

Mill Finished (Rough Material):

For those who appreciate the raw and industrial appeal, our mill-finished Aluminium Angle provides a rugged, unfinished look.

Natural or Matt Anodized:

Elevate the surface durability and enhance corrosion resistance with our natural or matt anodized finish, providing both protection and a sleek appearance.

Various Powder Coated Colors (RAL):

Add a burst of color to your projects with our powder-coated Aluminium Angle available in various RAL colors. Choose the shade that complements your design vision.

Electrophoresis Coating:

Opt for electrophoresis coating for a uniform and smooth surface finish. This process enhances both appearance and durability.

PVDF Coating:

For unparalleled protection against the elements, our PVDF coating ensures long-lasting resistance to weathering, fading, and corrosion.

Packing & Delivery

To protect the goods, we pack the goods at least three layers. The first layer is film, the second is carton or woven bag, the third is carton or plywood case. Glass: plywood box, Other components: covered by bubble firm bag, packing in carton.

fAQ